Throughout the years H2W has designed a number of custom motors and actuators, and should you require a motor or actuator that you don’t see in our standard listing, H2W can customize a design specifically to meet or exceed your needs. In addition, H2W has the capability to implement any motor or actuator into a positioning stage (Travel available from a few microns to over 10 feet, and precision down to 50nm).

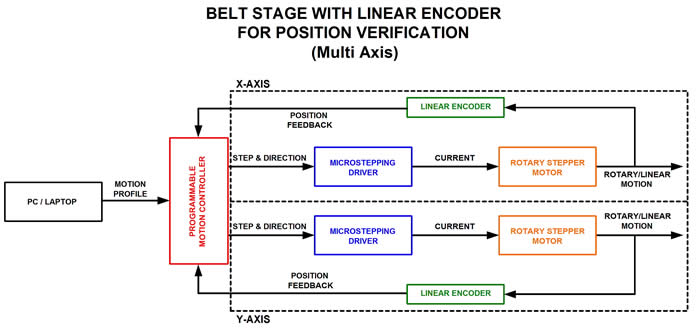

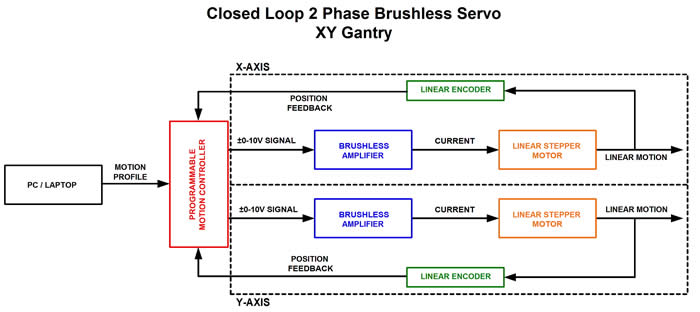

As well as providing the motor and/or stage to meet your needs, H2W has the expertise to provide the necessary drive electronics, and the capability to integrate the motion control electronics with the motion control stage in one to several axes, and having the ability to mix and match motor and drive types. These systems can operate in either open or closed loop applications, and every closed loop system is provided with startup programming. In addition, H2W will provide training and support to learn and successfully operate the motion control software.

From design to implementation, H2W provides the additional value that gets you started using your motion control device.

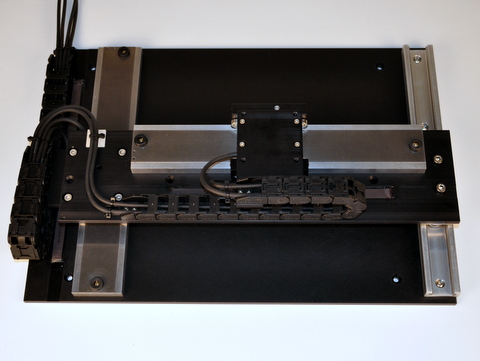

Example 1: Two Axis Open Frame Belt Stage Gantry |

|

|

This is a customized XY belt stage gantry using an open frame design. This specific belt stage gantry was designed to track an image of the sun on the inside of the frame. H2W is able to custom design a variety of linear motion stages and motion control systems to our customers' exacting specifications. SPECIFICATIONS: Travel = 40 in (1 m) each axis Speed = 0.1 to 200 in/s (300 mm/s) Payload = Up to 100 LBS Acceleration = 0.1 to 4 Gs Resolution = .00004 in. (1-micron) Accuracy = +/- 0.006 in/ft (typical) Repeatability = +/- 0.0004 in (typical) |

|

|

Example 2: Two Axis Closed Loop Two Phase Brushless Gantry |

|

|

This revolutionary new series of single axis linear stepper stages, which are also integrated in a variety of XY gantries, integrate a linear encoder into each single-axis linear stepper motor stage to operate the linear stepper motor as a 2-phase brushless linear motor, when coupled with state-of-the-art motion control electronics package provided by H2W. This allows H2W’s stage to achieve speeds and accelerations previously unachievable with a linear stepper motor (up to 5 G’s). The stage includes cable carrier to yield high cycle counts, there are also provisions that allow customer cables to be routed within the cable carrier, custom mounting hole on the moving table are available upon request at no additional charge, 1-micron resolution linear encoder, the stepper motor forcer and platen, bearings and a switch for home position, and optional end-of-travel limits are all integrated into a compact package, and cables are terminated in a standard 9-pin D-subminiature connector. Continuous forces are available with 6-lb, 10-lb, or 20-lb, or any combination of these forces. This package is low cost, and has a short lead time for custom lengths and/or options.

|

|

|